Shaanxi Forkrobot Manufacturing Co., Ltd is located in Gaoling District, Xi'an, covering an area of about 35,000 square meters. It focuses on the research and development and production of AGV/AMR unmanned forklifts. The factory currently has 4 specialized production lines, covering the entire process of body manufacturing, core component assembly, system integration and finished product testing, serving leading customers in the automotive manufacturing, e-commerce logistics, third-party warehousing and other industries.

Production line configuration and technical advantages:

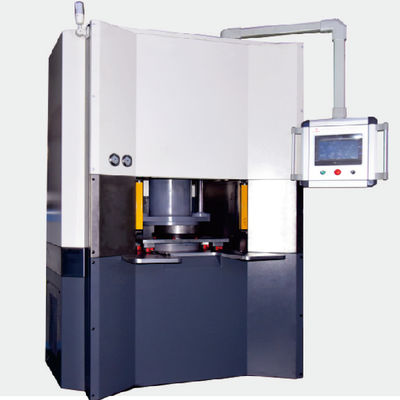

1. Core module assembly line (2 lines):

Equipment composition: motor drive assembly table, sensor calibration system, self-developed navigation controller burning station.Technical advantages: 100% automation of key workstations, using Industrial Internet of Things (IIoT) to achieve torque/current data traceability, and assembly error rate <0.05%.

2. Whole machine debugging and aging test line (1 line):

Equipment composition: 3D laser SLAM simulation scene cabin, cyclic load test bench, EMC anti-interference laboratory.Technical advantages: 72 hours of continuous aging test, passed CE/UL certification, navigation positioning repeatability accuracy ±5mm.

3. Staffing and skill level:

Number of workers: 6-10 people per line, 45 production technicians in the whole factory (including 8 engineers on-line support).Skill requirements: 90% hold mechatronics or industrial robot operation certificates, with an average of more than 3 years of experience in the new energy vehicle/AGV industry:Dress code: anti-static jumpsuit, safety shoes, RFID badge required in the test area (authority hierarchical management).

4. Capacity and management:

Daily capacity: 20 standard unmanned forklifts and 8 customized models (supporting flexible switching of 1.5T~5T load) off the line per day.5S management: implement the "digital twin + physical inspection" dual mode, use UWB technology for tool positioning, and the waste recovery rate is ≥98%.

The factory has passed the ISO 13849 functional safety certification and deployed the MES system to realize digital control of the entire production process. Its "5G+visual navigation" unmanned forklift series market share ranks first in the northwest region.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!